Method of early detection of defects in the HV circuit breaker mechanisms

HV circuit breakers in the energy systems belong to the most significant electric equipment. Quality of HV circuit breaker operation ensures safety and security of the entire power transmission system. Control and diagnosis of HV circuit breaker condition, timely identification of defects and their efficient repair become more and more significant.

HV circuit breaker diagnosis without special-purpose instrument is rather labor-intensive and does not give a general idea on the circuit breaker condition, therefore, once conventional methods for measuring the circuit breaker parameters (using a shuffle bar, a vibrograph and lamps) became obsolete and gave way to modern analyzers. Currently the market of instrumentation offers a large range of instruments of both Russian and foreign manufacture that differ in technical characteristics and cost. When selecting the equipment, the customer shall pay attention both to technical characteristics of an instrument, to its cost, service support, and on the quality of oscillograms on the HV circuit breaker condition.

A method for early diagnosis of defects in the HV circuit breaker mechanisms that was developed by the SKB EP Company, a manufacturer of instruments for control and diagnosis of HV equipment, has been successfully used in energy sector of Russia and CIS countries. This method allows early diagnosis of defects and detection of failures and even minor deviations in the operation of circuit breaker nodes that is based on the analysis of graphs constructed with the help of the instrument. The method consists in recording the travel of one of the elements of the mechanism (a moving contact, connecting rod, drive shaft, etc.) during the circuit breaker triggering, and comparison of the graph obtained to the graph of a properly operating circuit breaker, or to a graph constructed for this very circuit breaker during its latest test.

Graphic presentation of results has always been popular for HV circuit breaker control (e.g., time oscillograms on the photosensitive paper of a light-beam oscillograph, speed vibrograms drawn up using a vibrograph and a shuffle bar), but those graphs were not good for perception and needed preliminary manual processing.

Automatic measurements of speed characteristics using displacement transducers with high resolution produce quite different graphs: speed vs time, speed vs travel, travel vs time. They reflect the travel of a connecting rod and of moving contacts, their interaction with directing mechanisms, moving contacts and buffers. Hence, using the general view of the graphs and deviations from the reference graph you can make on-line diagnosis of those nodes.

Requirements to the HV circuit breaker state are specified by a manufacturer and appropriate codes and standards. Assessment of the current state of a circuit breaker (normal, below normal) implies identification of available deviations from manufacturer's parameters. Defect localization, its reference to a particular node of a mechanism, detection of incipient or concealed defects when parameter deviation yet lies within the reference values or reveals itself at certain moments only is possible on the base of analysis of graphs for the entire process of a circuit breaker triggering.

Different methods are used for assessing the state of HV circuit breakers, whereas special instruments, such as PKV/M7, PKV/U3.1 and PKV/U3.0 considerably facilitate and accelerate the circuit breaker diagnosis. These instruments allow recoding the time and speed characteristics of HV circuit breakers, and connecting rod travel graphs. These instruments considerably reduce the time of complex tests, raise their quality and allow grounded elimination of the unnecessary overhauls. Moreover, these instruments allow detection of concealed defects that are known to be the most hazardous ones.

Let us consider the method of early detection of defects in the HV circuit breaker mechanisms following the results of measurements using the PKV/M7 instrument in OJSC MRSK of Siberia, a Branch of Chitaenergo, Kashtak substation. The MKP-110P circuit breaker was under test.

In order to accurately detect a possible defect in the HV circuit breaker, the graphic and tabular data obtained should be analyzed in the closing and opening operations.

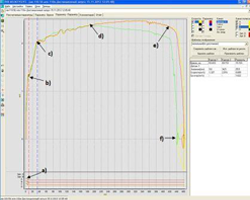

Fig. 1 shows a speed vs traverse travel graph for A, B and C phases during closing. Detailed examination of the graph reveals several important instances in the points a)...f):

Fig. 1. Opening operation

A graph of speed vs connecting rod travel for A, B and C phases

- "a" - means that contacts of phases "А" and "С" open at 6mm travel (it means that travel of springs for spring-loading the contact opened first is equal to 6mm). Phase C contact opens at 4mm travel (it means that travel of a spring for spring-loading the contact opened first equals 4mm). Contact opening delay is less than 1 mc (normal).

- "b" - means that on the 9mm travel we see the first gap in the speed increase. All the contacts of a chamber at this section evidently opened (spring-loading springs do not operate). Reference: Travel in contacts shall be 8±1mm.

- "c" - means that at 34.5mm travel we see the second speed gap. We assume that springs of a closing damper and opening springs do not operate at this travel.

- "d" - means that a connecting rod of B phase for some reason loses connection with the operating rod at 190mm travel. Presumably there is a clearance in the point of fastening the horizontal operating rod to a connecting rod of pole B.

- "e" - means that at a section from c) to e) only drive opening springs are in operation.

- "f" - means that phase B travel is 20mm lower than travel of A and C phases.

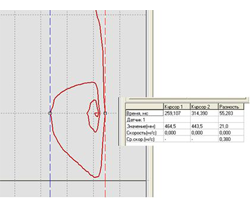

Graph of phase A connecting rod travel (Fig. 2) shows that a phase tripping buffer rebound makes 21mm (the value can be taken from the table by placing two cursors on the graph edges). The buffer is presumably not operable. The nature of rebound looks like the metal falls on metal.

Fig. 2. A graph of Phase A connecting rod travel

- Till the moment of bumping against lower contacts of a chamber a connecting rod of phase B passes the distance 8.5mm less than connecting rods of phases A and C.

- Speed graphs of A and C phases practically overlap, whereas that of Phase B does not. It can mean that connecting rods of A and C phases are rigidly connected to an operating rod, whereas a connecting rod of phase B does not.

- Phases closing buffers operate normally. Operation of A and C buffers is close to ideal, whereas the buffer of Phase B probably lacks oil (one swing more).

- Wavy nature of a graph at the initial stage may be due to slackness of phase B. That is, an operating rod pushed this Phase B connecting rod that bounces back and creates shocks that are transferred to Phase B connecting rods of A and C phases.

- Phase B graph at chamber contacts spring-loading is still difficult to interpret (we mean the smooth curve rounding as compared to peaks on the reference curves).

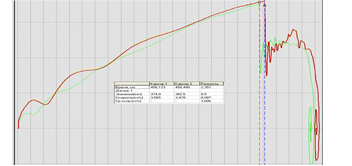

Fig. 3. Closing operation

Speed vs connecting rod travel graph for A, B and C phases

Let us take data (Table 1) on the travel up to contacts closing when a transducer is connected to different poles (A, B and C), and compare them.

|

DP12 location |

Phase A |

Phase B |

Phase С | |

|

Travel up to contacts closing, mm |

А | 454.0 | 446.0 | 454.0 |

| В | 455.5 | 448.0 | 455.0 | |

| С | 455.0 | 448.0 | 455.0 | |

|

Difference between B and A phases |

Difference between B and C phases |

|||

| А | -8.0мм | -8.0мм | ||

| В | -7.5мм | -7.0мм | ||

| С | -7.0мм |

-7.0мм |

||

Figures to be used for comparing the phases travel with respect to one another are given in bold. It is due to the fact that irrespective of the phase of a transducer mounting the program generates data for all the three phases. Therefore, for accurate determination of the connecting rod travel, take the travel data from the appropriate column, where this phase is indicated. For example, if a transducer was mounted on the A phase, the data on the connecting rod travel shall be taken from "Phase A" column and "Travel to contacts closing, mm, A" row, i.e., 454.0mm.

After analysis of Table 1 we can conclude that up to contacts closing the phase B connecting rod travels 7-8mm less than connecting rods of A and C phases. In may happen only if plugs of phase B connecting rod are elevated by 7-8mm or the chamber of this phase is lowered by the same distance.

Analysis of data obtained on the circuit breaker at triggering and tripping operations allows us to conclude that at phase B there is a clearance in the point where the drive operating rod is fastened to a circuit breaker connecting rod; owing to this clearance, against triggering command the phase B connecting rod starts moving later than connecting rods of A and C phases. As a result the contacts are closed later. To avoid this delay of contacts closing it is necessary to eliminate clearance between connecting rod and operating rod of phase B.

Thus, we can conclude that the method of concealed defects diagnosis based on the graph analysis is simple, reliable and obvious. Using the graphs you can identify faults and deviations at early stage of their origin and ensure more efficient schedule of maintenances. Even minimum experience in graph analysis allows identification of nodes and elements of a circuit breaker that need repair prior to its commencement, allowing you to avoid unnecessary (sometimes risky) disassembly of operable nodes, thus reducing the time and cost of repair.

The method for early diagnosis of concealed defects in the HV circuit breakers was many times highly appraised by users of the instruments where this method is applied: FSK ES Mosenergo; OJSC Yakutskenergo; OJSC Krastsvetmet; CJSC Spetselektromontazh; OJSC Uralelektrotyazhmash; OJSC Tulenergokomplekt; OJSC Branch of OGK-3 of Khabarovsk HPP; East Siberian Railway; OJSC Tulenergo; OJSC RAO EES of Russia; OJSC Vologdaenergo Branch of Vologda Heat Supply Network, and many others (references→).

Русский

Русский

Français

Français

Chinese

Chinese