Cost-efficient HV circuit breaker maintenance using the early fault detection method

"Non destructive methods of HV circuit breaker control developed and implemented by the SKB EP Company are an efficient means for detecting the faults and defects in the HV circuit breakers, which reduces equipment maintenance and operating costs"

V.V.Kostin, Chief Engineer of OJSC Tulenergo

Companies operating power equipment face big challenges as major equipment has become obsolete and physically worn out. Investments into new equipment are minor; the number of maintenance personnel is being reduced. Service life of about 40% of oil and air circuit breakers (mainly of 110 and 220kV) specified by standards and codes has expired, while only 55% of the entire circuit breaker stock is planned to be replaced by 2015.

The SKB EP Company deals with development and manufacture of instruments for non-destructive control of HV circuit breakers (the PKV family). Instruments of the PKV family allow circuit breaker diagnosis without its disassembly, without oil discharge and without disconnection of bypass resistors. They test all the mechanical details and nodes of a circuit breaker at a time, and control several characteristics of a node simultaneously (time and travel parameters). Prior to diagnosis the voltage shall be disconnected and a circuit breaker shall be earthed.

Graphs obtained with the help of special-purpose instruments (such as PKV/M6, PKV/M7, PKV/U3.1 and PKV/U3.0) are used for the circuit breaker condition analysis. This method is referred to as a method of early detection of defects in the HV circuit breaker mechanisms. This method is based on the analysis of graphs obtained with the help of the instrument and allows early detection of defects and even minor deviations in the circuit breaker nodes. The method consists in recording the displacement of one of the elements in the mechanism (moving contacts, a connecting rod, drive shaft, etc.) during the circuit breaker triggering and comparison of the graph obtained to a graph of a properly operating circuit breaker or to a graph recorded for this very circuit breaker during its latest test.

Graphic presentation of results has always been popular for HV circuit breaker control (e.g., time oscillograms on the photosensitive paper of a light-beam oscillograph, speed vibrograms drawn up using a vibrograph and a shuffle bar), but those graphs were not good for perception and needed preliminary manual processing.

Automatic measurements of speed characteristics using displacement transducers with high resolution produce quite different graphs: speed vs time, speed vs travel, travel vs time. They reflect motion of a connecting rod and moving contacts, their interaction with guiding mechanisms, with moving contacts and buffers. Hence, its general view and deviations from the reference graph allow on-line diagnosis of those nodes immediately after putting the circuit breaker out of operation.

Benefits of the instruments include:

- Lower costs of HV circuit breaker maintenance (by a factor of 1.5);

- Lower (almost halved) time of the circuit breaker testing;

- Use of the PKV instruments in some cases allowed complete elimination of unnecessary overhauls as they diagnosed proper condition of a circuit breaker.

Requirements to the HV circuit breaker condition are specified by a manufacturer and by the appropriate codes and standards. Assessment of current condition of a circuit breaker (normal, below normal) implies detection of deviations from manufacturer's parameters. But detection of incipient or concealed defects when parameter deviation still lies within the reference (specified in passports) allowances or reveals itself in certain instances only, is possible only on the base of analysis of graphs for the entire process of a circuit breaker triggering.

There are different methods for assessing the condition of HV circuit breakers, but special instruments, such as PKV/M6N and PKV/M7 are most convenient for the circuit breaker diagnosis. These instruments considerably reduce the time of complex tests, raise their quality and allow grounded elimination of unnecessary overhauls. Moreover, the PKV/M6N and PKV/M7 instruments allow detection of concealed defects that are known to be the most hazardous ones.

"The method is simple, reliable and demonstrable. It saves time and we plan its further use in our company".

S.V. Melnikov, Head of Electric Laboratory of OJSC RAO EES OF RUSSIA,

Vologdaenergo Branch, Vologda Heat and Power Supply Network

"Application of these instruments considerably reduces labor for measuring the monitored parameters of circuit breakers during scheduled maintenances, overhauls, and inter-repair tests, and allowed elimination of obsolete procedures and tools that were widely used before. During their use at the East Siberian Railways the instruments demonstrated high accuracy of parameters measurements and high reliability of operation".

V.A.Dranitsa, Head of Electrification and Power Supply Service of the East Siberian Railways

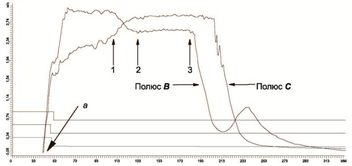

The method can be illustrated on the MKP-110M oil circuit breaker. Graphs below show speed characteristics and oscillograms of contacts closing-opening across A, B, and C poles.

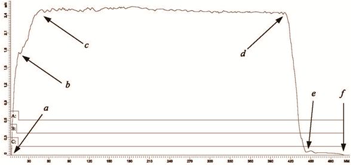

Fig. 1. A graph of triggering the properly operating circuit breaker

On the graph of triggering the properly operating circuit breaker (Fig. 1) five characteristic sections can be singled out (marked with lettered arrows): from the start of motion to the 'b' point, the ab, bc, cd, de, and ef sections. If time sweeping were used, then one more section would be present on the graph, namely, a section from the moment of a command impulse to the starting motion (section 0 a). The processes occurring on separate sections are:

- 0a section. OPEN command and its execution by a drive. This section shall be analyzed on a graph together with time sweeping. Command execution by a drive terminates in point 'a'.

- ab section. Operating and connecting rods are accelerated by the action of contact springs, springs of arch extinction devices, and by opening springs. Contacts open in 'b' point.

- bc section. Springs of contacts have stopped acting and further acceleration of operating and connecting rods is due to springs of arch extinction devices, and opening springs.

- cd section. Springs have stopped acting and further acceleration of operating and connecting rods is due to inertia and gravity.

- de section. An oil buffer is actuated that absorbs speed of operating and connecting rods.

- ef section. The oil buffer continues its action. Operating and connecting rods under gravity slowly move to the 'f' point to stop.

This graph of speed allows check of the operation of contactor springs, springs of the arch extinction devices, opening springs, as well as lack of nippings in the guiding device, and oil buffer operation.

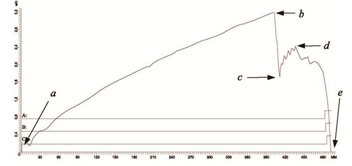

Fig. 2. A graph of properly operating circuit breaker triggering

Five sections can be singled out on the graph of a properly operating circuit breaker triggering (Fig. 2). Processes occurring in them include:

- 0a section. Drive actuation delay. This section shall be analyzed together with time sweeping.

- ab section. Operating and connecting rods accelerate under the impact of an electromagnetic drive.

- bc section. In the 'b' point the moving contacts touch the lower contacts of the arch extinction devices. The speed drops due to higher mass of moving parts.

- cd section. Acceleration of the connected rod by an electromagnetic drive continues but it moves together with moving contacts of the arch extinction devices.

- de section. An electromagnetic drive stops its operation. The opening springs, springs of arch extinction devices, and contactor springs are loaded. In the point 'e' the operating and connecting rods stop.

Knowledge on the behavior of a properly operating circuit breaker during triggering and tripping (graph behavior during triggering/tripping) allows detection of the circuit breaker faults with the help of graphs analysis.

If there is no graph of a properly operating circuit breaker but there is a graph of its previous test, then comparison of these graphs would show the tendency of changes and would allow us to forecast its future behavior.

Let us consider some examples:

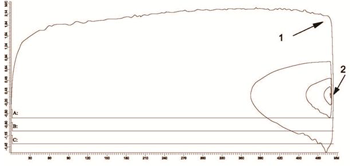

Fig. 3. A graph of a circuit breaker tripping with an inoperable oil buffer

The above graph (Fig. 3) shows that in the circuit breakers with an inoperable oil buffer the arm bumps against the buffer, and a operating and connecting rods perform multiple reverse motions until they stop (df section of a properly operating circuit breaker (Fig. 1) degenerated into a spiral 1-2).

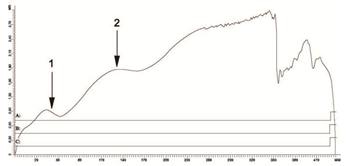

You can also detect availability of 'nippings' on one of the poles (a concealed defect) that is caused, for example, by strongly pressed jaws of a guiding device. This defect is well seen on the speed vs travel graph (Fig. 4). Speed gaps on the graph (points 1 and 2) evidence that nipping occurred at travels of (41…62) mm and (131…182) mm.

Fig. 4. A graph of a circuit breaker triggering with strongly pressed jaws of a guiding device

Clearances, a heavy defect of moving parts, are also detected by the PKV/M6N and PKV/M7 instruments. Clearances create an intermittent load from the mechanisms of three poles on the common drive through which three motion processes interact, which is very well seen if you overlap 'speed vs time' graphs of two or three poles (Fig. 5).

Fig. 5. Overlapped graphs of two poles opening

The mechanisms of poles interact in the following way. After the motion starts due to poor condition of an arch extinction device or opening springs, the operating and connecting rods of the C pole move slower than the operating and connecting rods of the B pole. By the time moment of point 1 the clearance between poles is taken up. The moving masses interact. One operating rod with a connecting rod gets an accelerating impulse, and the other one - a decelerating impulse. Starting from this time moment the speed of connecting rods changes accordingly. And by the time moment of point 2 the speed of operating rods with connecting rods stabilizes, but they are different again. A connecting rod of the pole C now moves even faster that the connecting rod of pole B. The clearance is taken up in the opposite direction. At the time moment of point 3 the operating rod with a connecting rods is decelerated by an oil buffer. But a connecting rod of the C pole is still moving at a high speed. By the time moment of point 4 the clearance is taken up completely. The moving masses interact. An operating rod with a connecting rod of the C pole gets a decelerating impulse, and an operating rod with a connecting rod of the B pole gets an accelerating impulse. This fact accounts for the speed jump at the deceleration section of the B pole, and availability of "teeth" due to intensive impact on the deceleration section of the C pole.

"Speed vs time" graph allows identification of one more defects, namely, extended time of the circuit breaker triggering. Fig. 5 shows the 0a section from the moment of a command to the moment of movement start. During this time interval the drive executes the "opening" command, though the operating rod with a connecting rod does not move yet. Command execution by a drive terminates in point 'a'. If the 0-a interval exceeds a specified value determined using the graphs for properly operating circuit breakers, then the defect is in the drive. If this interval does not exceed a specified value, then the defect is due to the fact that one of the nodes of the mechanism transmits the motion from a drive to the moving contact. To determine that, the 'speed vs time' graphs are analyzed using the method described above.

Thus, it can be concluded that the method of concealed defects detection by analysis of graphs obtained using the PKV/M6N and PKV/M7 instruments is simple, reliable, demonstrative and saves a lot of time.

Using the graphs you can detect failures and deviations at early stage of their origin and ensure more efficient schedule of maintenances. Even minimum experience in graph analysis allows detection of nodes and elements of a circuit breaker that need repair prior to its commencement, allowing you to avoid unnecessary (and sometimes risky) disassembly of operable nodes, thus reducing the time and cost of repair.

"Our opinion on advisability of using these instruments is unanimous: THEY MUST BE APPLIED"

Chief Power Engineer of OJSC Krastsvetmet, B.G. Buzaev

The method described and the PKV/M6N and PKV/M7 instruments for early diagnosis of concealed defects in the HV circuit breakers were many times highly appraised by users of those devices: FSK ES Mosenergo; OJSC Yakutskenergo; OJSC Krastsvetmet; CJSC Spetselektromontazh; OJSC Uralelektrotyazhmash; OJSC Tulenergokomplekt; OJSC Branch of OGK-3 of Khabarovsk HPP; East Siberian Railways; OJSC Tulenergo; OJSC RAO EES of Russia; OJSC Vologdaenergo Branch of Vologda Heat Supply Network, and many others (references→).

Русский

Русский

Français

Français

Chinese

Chinese